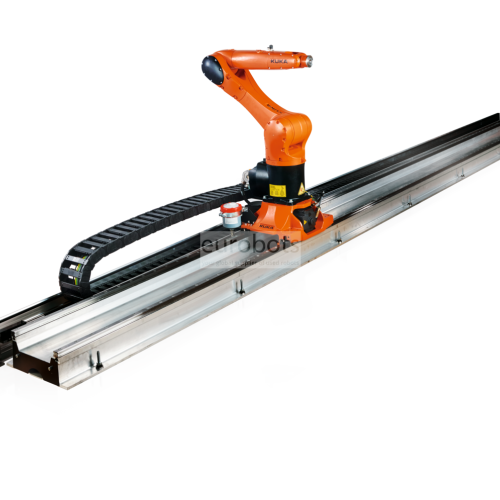

KUKA KL100 Linear track

Extend your reach. Multiply your productivity.

KUKA linear units dramatically expand robotic workspaces, allowing a single robot to cover multiple stations or processes along a production line. Implemented as an external axis, these linear units require no additional controller, reducing system complexity and cost.

The KUKA linear unit portfolio covers all payload classes and application needs, ranging from ceiling-mounted solutions and high-speed variants to protected versions for demanding industrial environments. This versatility gives you full freedom to design scalable, future-proof automation systems.

Key Advantages

High precision

Up to four robots can operate on a single linear axis. Multiple programmable positions along the axis enable precise adaptation to existing layouts and process requirements.

Maximum flexibility

Long travel lengths extend the robot’s effective working area far beyond its standard reach, making linear units ideal for connecting and servicing multiple production stations.

Versatile installation

Available in floor-, ceiling-, and wall-mounted configurations. Optional protective covers shield the system from dirt, dust, and harsh environmental conditions.

High performance

Special variants are available for high-torque applications such as milling, as well as high-speed versions for extremely short cycle times.

Increased productivity

Additional driven or non-driven carriages (tender carriages) enable the transport of workpieces or tools, reducing idle time and further optimizing cycle times.

The KL 100 is a compact and high-precision linear unit designed specifically for the KR AGILUS robot series. It can be installed on the floor, ceiling, or wall, offering maximum flexibility in cell design. With a payload capacity of up to 100 kg, the KL 100 is ideal for fast handling, pick-and-place, and automation tasks where speed and accuracy are critical.

By extending the robot’s working range along an additional axis, the KL 100 significantly increases productivity while maintaining a small footprint. The unit is integrated as an external axis, eliminating the need for an additional controller and simplifying system integration.

Области применения

Дуговая сварка , Точечная сварка , Поддержка прессы , Погрузка и разгрузка деталей , Обработка , Обработка деталей , Измерение , Сборка деталей , Лазерная резка , Склеивание - склеивание , Приварка шпилек , Плазменная резка , Advanced Manufacturing , Education , фрезерная ячейка

Картинки

Диаграммы

English

English

Spain

Spain

Germany

Germany

France

France

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa